Hardware Integration Services

We provide the service of integrating from designing the embedded system circuits (based on imaging and wired/wireless communication) to mass production.

We provide hardware development service in these steps: customer requirements analysis, circuit design, board manufacturing, testing, and quality certification.

CIRCUIT DESIGN

We analyze customer requirements, determine the circuit elements to use, and design circuits corresponding to a product concept.

Core Technology

ARM Cortex-A/M/R series, MIPS series

FPGA/ASIC/DSP design

Image Processing and Image Format conversion technology

Power & Signal Noise, EMI, EMC applied design

Analog/digital circuit design

WIFI/BT, GPS, LTE-CAT M1 design

Circuit simulation

Using ORCAD, PADS

PCB DESIGN

It is the stage of embodying the designed circuits onto a board (printed circuit board). The CAD program is used to arrange the locations of) parts on the board. And the wiring design is carried out for the parts. As the PCB design can affect the performance, functions, service life, and reliability of a product using the board, it is important that the PCB design is highly complete in quality as well as it meets the development schedule. After designing the PCB completes, simulation is undertaken to find if there is an error in the signal lines or power units.

Core Technology

BILD UP PCB design

1 ~ 15 LAYER design

High Speed Board Design : MIPI, DDR design

RF Board design

Impedance Board design

EMC matched design

Design for PCB mass production

ARTWORK TOOL : PADS, Mentor etc.

PBA production

SMD(Surface Mount Device)

SMD is an electronic device for which the components (or surface mount components) mounted or placed directly onto the surface of the PCB.

Assembling/Test process

As one of the assembling processes, this is the process of assembling the PCB and PWB printed wire board) with SMT(surface mount technology) and making it into a module that can work electrically through post-processing and data upload.

PERFORMANCE VERIFICATION

SMD undergoes several reliability tests such as performance, wired/wireless communication, thermal shock, thermo-hygrostat, EMI, and ESD. It is to know whether it satisfies the product requirements.

← Scroll left and right →

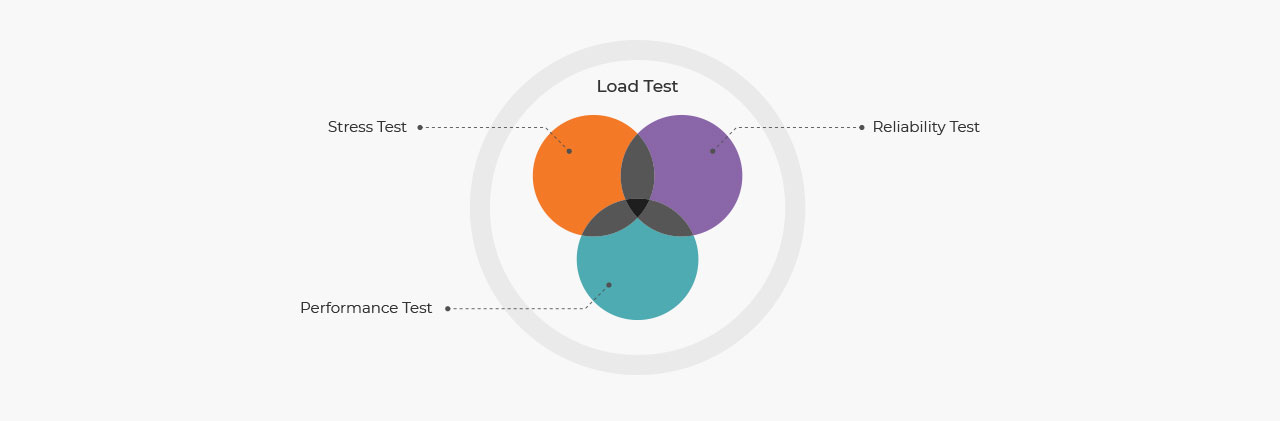

Load Test

It measures statistically significant values with load artificially applied. Two purposes ask for this test: one is reliability (how long it can serve) and the other is performance.

Stress Test

It applies more load than expected during normal use, which exceeds the allowable limits of the resources (CPU, RAM, Disk, etc.) engaged when the application runs.

Performance Test

It measures, finds, and interprets the point where TPS does not increase anymore as load gradually increases.

Reliability Test

It checks if a product works as expected under general and particular circumstances.

SUCCESS STORY

SMART HJC 10A

Helmet-type Action Camera

SBS-V1

Smart medical equipment of BLE- based multi-biometric signal transmission

CHANUN-AIR

Smart IOT Car Air-Purifier

CHANUN1/2/2(wifi)

Black Box

Semisolution

Coming soon.

Semisolution

Coming soon.